Permali & Airbus: Tactical Excellence

In 2025, Permali was approached by a leading aerospace organisation (Airbus) to support a major military aircraft programme requiring an upgraded tactical hard flooring system for their H145M helicopter.

Building on similar composite flooring work we have delivered previously, we were tasked with developing a solution capable of withstanding the demanding conditions of a military helicopter environment. The flooring had to withstand intensive operational use, including high foot traffic, heavy equipment loads, impact, exposure to fuels and hydraulic fluids, and rapid changes in environmental conditions. Turnaround time, reliability, and precision manufacturing were critical to the project’s success.

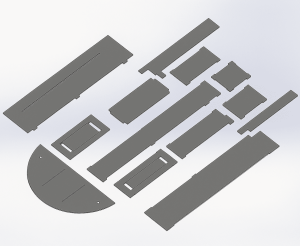

Permali designed and manufactured a lightweight composite hard‑flooring solution tailored for the rotorcraft’s cabin environment. Using proven Permaglass composite technology, the panels deliver high strength‑to‑weight performance, excellent impact resistance, and long‑term durability.

Each panel is completed with a textured, grit–reinforced coating designed to deliver long–lasting grip and abrasion resistance, ensuring reliable footing in all mission conditions. The flooring system integrates seamlessly into the aircraft structure while meeting strict defence and aerospace standards.

Customer Requirements & Initial Concept

The project began with a detailed concept package from the customer, outlining specifications, regulatory guidelines, material and thickness requirements, and expectations for how the panels would be installed. This also included a list of all required aircraft configurations and identified which panels needed to be removable to support rapid role fit capability.

Design Development

Using the customer’s STEP files, our engineering team translated the concept into a flooring layout. Each design decision was checked against the Technical Compliance Matrix to ensure full alignment with performance, installation, and certification requirements.

Physical Verification & Trial Fits

To validate accuracy early, we produced full-sized panel mock-ups. These allowed both teams to confirm geometry, installation sequencing, and how the removable sections functioned within each configuration before committing to composite production. This is a routine process for Permali when integrating to any new program, as every platform has its challenges, which are best found in person with mock ups.

Compliance & Final Engineering

The material has been formulated/ engineered to withstand stringent CS 25.853 flammability requirements, while not sacrificing weight and durability. Ensuring every possible panel arrangement fitted successfully, required close attention to detail at the design phase and accurate machining to tight tolerances during production.

Collaboration

Collaboration was key from the start, given the necessary modularity required for the panels to be interchanged depending on role fit and mission objective. This collaborative and iterative approach resulted in a flooring solution tailored to multirole aircraft operations.

Key Product Features

- High strength‑to‑weight ratio

- Durable composite construction

- Impact and abrasion resistance

- Chemical resistance (fluids, oils, fuels)

- Precision tolerance manufacturing

- Optional non‑slip textures and surface finishes

- Customisablepanel geometry

- Rapid role fit capability

The Benefits of THF

Protection of the Original Cabin Floor

Permali’s flooring system provides a robust protective layer that shields the OEM floor from damage caused by heavy equipment, high foot traffic, and mission‑specific loads. By reducing wear and impact-related degradation, the solution helps extend the aircraft’s operational life and minimises maintenance interventions.

Enhanced Safety Through a Durable, Non‑Slip Surface

The composite surface is engineered to deliver reliable grip and long‑term durability, supporting safe movement for crew and passengers in demanding scenarios. Its resistance to fuels, oils, dirt, and abrasion ensures dependable performance throughout sustained operations.

Adaptable for Multi‑Role Mission Profiles

Designed with flexibility in mind, the flooring can be installed or removed quickly to support a range of mission configurations, including cargo transport, troop movement, and medical evacuation. Optional integration points allow for tie‑downs, rails, and equipment mounts where required.

Optimised Weight and Load Distribution

The system is engineered to withstand high point loads from mission equipment and personnel in full gear. By distributing weight effectively across the floor structure, it provides additional protection to the underlying sub‑floor and supports reliability across varied mission demands.

Sectors & Applications

Our tactical hard flooring solution offers unmatched versatility for rotor and fixed-wing aircraft. It is highly configurable and serves a wide range of sectors and operational scenarios including:

- Air Ambulance

- Cargo

- National Police Air Service

- HM Coastgaurd

- Search & Rescue

- Off-shore Oil & Gas

- Military Operations

- Utilities

- Agriculture

For more information, please contact sales@permali.co.uk