Offshore

Offshore Guard Rail & Safety Nets

For over 25 years Permali has been supplying high-strength, glass fibre-reinforced (GRP) composite Stanchions, Guardrails and boat rail safety netting used in some of the most demanding environments in the world.

Oil rigs see incredibly harsh conditions, with extreme weather and temperature changes, strong winds and high precipitation and salinity. Helipads, walkways and stairs are some of the most vulnerable parts of the rig where staff are at most risk – guard rail netting, stanchions and rail safety netting systems undergo serious punishment exposed on the outside of the rig, with material performance being vital in ensuring the safety of staff.

Permali’s innovative GRP composite materials offer superior attributes to conventional iron and stainless steel and include the following design benefits:

Corrosion resistant

Lightweight

High strength

Quick release options

Rigid systems

Foldable systems

Camlock

Dielectric properties

Offshore

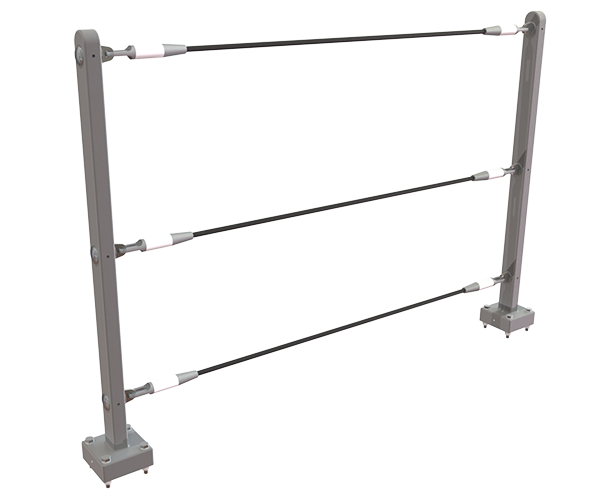

Stanchion systems

Permali also supplies bespoke walkway safety systems, incorporating modifications to suit the type of platform and specific requirements such as rail height, number of handrails and type of hinge points. Marine composites play a crucial role in these customisations, ensuring both strength and lightweight performance.

Stanchion systems are supplied by Permali ‘ready to install’, complete with all the fixings, fittings and lug bolts required for the guardrail design and specification. All fabricated composite stanchions, rigid guardrails and rail safety netting frames are finish painted in-house with a two-part polyurethane paint to the customer’s desired colour.

Offshore

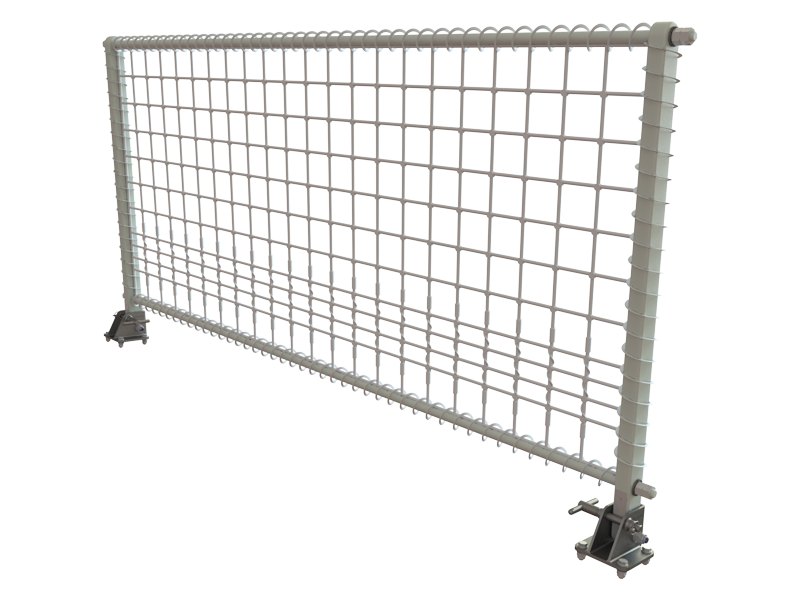

Safety netting systems

Capable of withstanding harsh conditions, all net systems use a combination of a cast stainless steel base with a lightweight, painted GRP composite frame, which provides a low maintenance, corrosion-free system. Permali specify ‘camlock design’ fittings for its boat rail safety netting systems, for added safety as they are positively locked in the upright and deployed positions.

Added ‘safe refuge’ protection for staff in bad weather conditions is provided usinga shock cord woven into the lower sections, which allows the net to “sag when necessary”.

Our rail safety net systems also come with the option of being fully automated.

Bespoke solutions for Offshore

Designed and manufactured at a single site in Gloucester, UK, Permali provides a full new product development (NPD) service, which can rapidly design and test new products for oil rigs and other Offshore applications. Marine composites are integral to these solutions, providing the necessary durability and performance. The R&D, design and process engineering teams have extensive experience in working under pressure with defence sector OEMs. Permali has demonstrated its added value to customers by accelerating NPD projects using its specialised innovation team, carrying out in-house material properties testing and providing prototypes in short lead times.

Most recently Permali’s R&D team has developed Permaglass® XGR2/4, a new specialist FR composite material grade, which provides the next generation safety fire performance.