Composite Appliqué Armour Solutions

Composite Armour

Appliqué & Blast Protection (Add-On) Armour

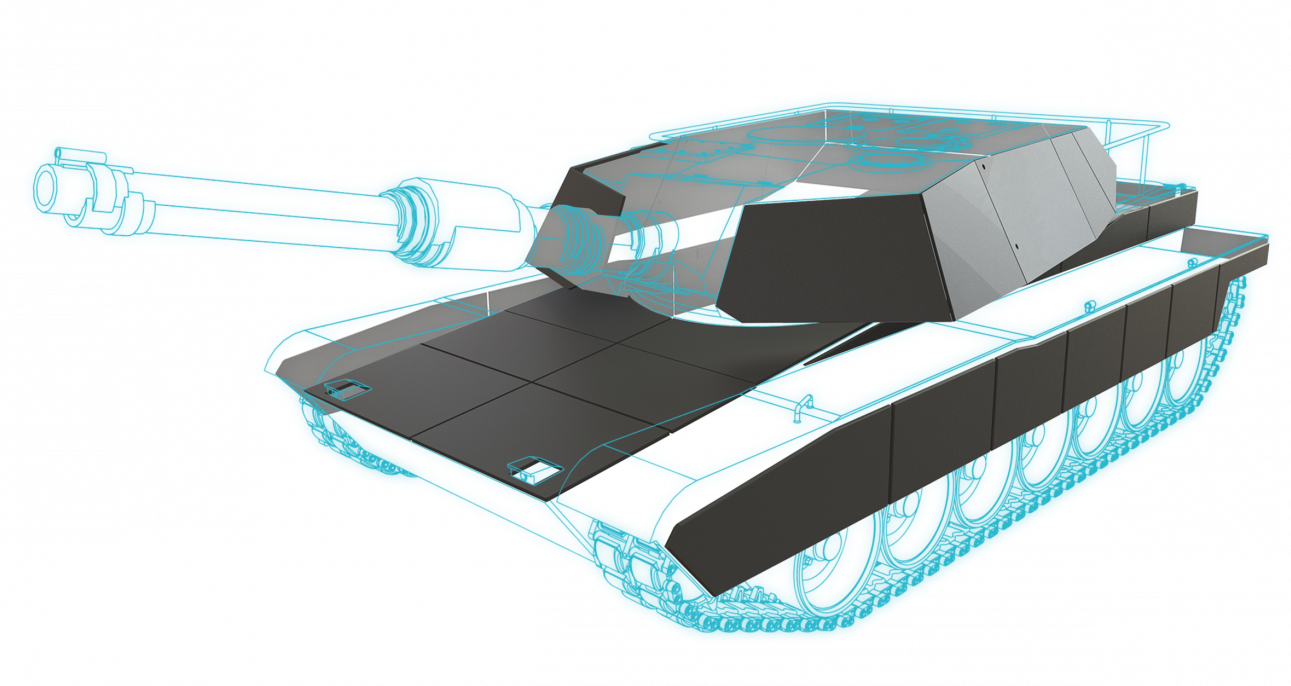

Permali is the UK’s leading supplier of lightweight appliqué armour solutions for land, sea and air defence sectors to the UK Ministry of Defence (MOD), EU, NATO and US defence (add-on armour). Permali composite armour and blast protect products are subjected to rigorous environmental, ballistic and safety tests to ensure that meet the required EU, US, UK and NATO standards. We have a long-established global reputation as an innovative designer and manufacturer of lightweight anti-ballistic and blast-resistant advanced composite fibre-reinforced (FRP) materials and fabricated appliqué armour systems.

Our expert team of material scientists and design engineers work closely with the military and defence sector manufacturers to develop vehicle armour systems which improve protection levels and minimise weight.

Different armour solutions are needed to meet the specific application requirements of each defence sector. Permali provides tailored ballistic vehicle protection and blast appliqué armour solutions for the different types of armoured vehicles, warships and combat aircraft.

Permali products are currently being used by armed forces all around the world for combat, anti-terrorist and UN peace-keeping activities. These include appliqué composite armour panels, underfloor blast-resistant armour and spall liners.

Composite Armour

Production Capabilities for Composite Armour Systems

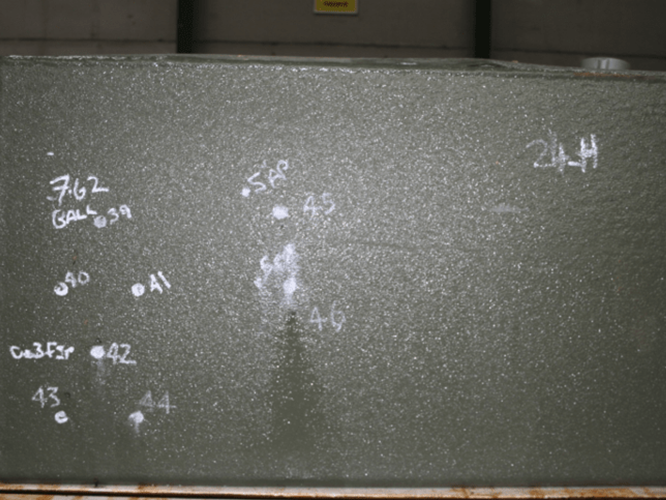

Permali’s extensive materials processing capabilities include FRP laminate sheet pressing, vacuum infusion, closed moulding and CNC routing/water jet cutting of complex-shaped advanced composite armour parts. Permaglass® ballistic vehicle armour plating systems are precision-made to fit the different specifications and design geometries of military vehicles, naval vessels and combat aircraft.

Armour-grade Permaglass® laminate sheet and sandwich panels are combined with ceramic armour plating, steel and aircraft-grade aluminium materials, offering high-velocity anti-ballistic protection levels ranging from small arms to heavy machine guns as required. Speciality prepreg fibre reinforcements, thermoplastics, ceramic plates and coating materials used by Permali for manufacturing integrated Permaglass® composite appliqué amour systems include:

Ballistic and blast grade Permaglass® composite stock sheets or custom moulded, CNC machined flat and curved armour panel kits are produced to order for defence and security sector manufacturing companies.

Sub-assembly armour components can be supplied with metal insert fixings, Tufshield® coated or painted.

Composite Armour

Ultra-lightweight Ceramic-Composite Aircraft Appliqué Armour

Ballistic and blast protection armour panelling is fitted inside an aircraft behind the fuselage. For land and naval defence armour, weight is less critical than for aircraft, especially helicopters.

To provide the lightest ballistic resistant armour system possible, low–density silicon carbide or even lower-density boron carbide advanced ceramic plates are used by Permali for aircraft armour systems; lower–density ceramic plates are more mass efficient, so can produce lighter, higher performing anti-ballistic armour.

Permali supplies lightweight aircraft appliqué armour that is easily installed and removed to save weight when not needed. Armour systems are developed for both new aircraft models and to upgrade the protection level of in-service planes and helicopters. All Permali aircraft armour systems meet FAR/CS25 and FAR/CS29 regulatory standards.

Defence Sector

Appliqué Armour Applications

Permali has designed and manufactured numerous spall liner and ballistic armour solutions for different types of MOD and NATO armoured vehicles including:

- MOD armoured fighting vehicles (AFVs) such as: Viking, Warthog, Challenger 2, Bulldog, Trojan, Titan and Warrior platforms for the British Army

- Medium and light protected patrol and infantry vehicles such as: VBCI Nexter and Aravis armoured infantry vehicle for the French Army and all MoD Foxhound patrol vehicle models for the British Army

- EOD (Explosive Ordnance Disposal) and Counter Improvised Explosive Device Disposal (CIEDD) vehicles – small arms fire anti-ballistic and mine/IED blast protection chassis armour, such as for the MoD Wedgwood CIEDD

Logistical support vehicle cab armour – ballistic, mine and bomb fragment armour protection for lorries and fuel tankers, such as the Oshkosh cab for Heavy Equipment Transporters (HET) and tankers.

Permali design and develop ballistic protection systems for storage areas on ships for ammunition, high explosive charges and pyrotechnics. Armour systems are designed to meet a variety of combat threats including sniper attack.

Naval vessels in service around the world fitted out with Permali ballistic protection and desk safety products include: aircraft carriers, helicopter carriers, corvettes, frigates, destroyers.

Bespoke aircraft armour solutions have been developed by Permali for both new aircraft models and as appliqué armour to upgrade the protection level of in-service planes and helicopters. Examples of successful applications where Permali ballistic armour has been supplied include:

- CH-47 Chinook transport helicopters for the Royal Air Force (RAF) and Royal Netherlands Airforce (RNAF)

- Royal Navy (RN) Sea King helicopter fleet

- AW101 Merlin combat helicopter ballistic system for RAF and RNLAF

- RN Commando Merlin Mk4 battlefield helicopter

Bespoke Design Service

Permali has R&D, design engineering and processing expertise and facilities to rapidly design, test and supply new armour products to meet ever changing defence sector needs. Bespoke solutions are developed to specific customer design and performance specifications to meet MOD, NATO and other regulatory standards required.