![]()

New Permali composite flight deck safety systems meet the latest UK MoD fire retardancy standards for Royal Navy vessels.

Permali is the global market leader in the design and manufacture of high strength, glass fibre reinforced (GRP) composite stanchions, guardrails, deck safety net frames and ladder systems for naval warships and support vessels. UK MoD fire retardancy (FR) standards have become even more stringent since the first Permali composite stanchions were fitted on the decks of Royal Navy ships more than 30 years ago.

To meet the latest UK MoD regulatory standard to improve naval crew fire protection, Permali’s R & D team has developed Permaglass® XGR2/4, a new specialist FR composite material grade, which provides the next generation naval safety fire performance. Extensive mechanical and fire, smoke and toxicity (FST) testing to the new Defence Standard 07-247 has been carried out to validate the new material’s suitability for the demanding deck safety applications.

Figure 1: Close up shot of fabricated finished painted GRP composite stanchions

New MoD FST Def standard

Defence Standard 07-247 is the latest, more stringent MoD fire, smoke and toxicity (FST) performance standard for naval vessels. Permaglass XGR2/4 achieved the highest overall Category A1 rating possible for this enhanced FST Def standard; critically XGR2/4 fire test coupons achieved Class 1 for surface spread of flames (to BS 467 Part 6) and a fire propagation index (I) of 7.8 (to BS 467 Part 7).

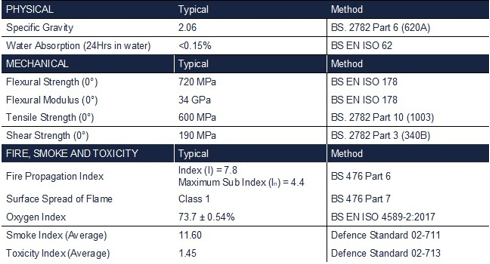

Equally impressive is that Permali’s innovative new Permaglass XGR2/4 resin grade and laminate system achieves this higher FST rating while still easily meeting the demanding mechanical performance requirements of the MoD standard. Permali has been able to do this by combining its proprietary high performance, low VOC thermoset FR resin formulation with woven glass reinforcements. Typical mechanical properties listed by Permali in the published technical data sheet for Permaglass XGR2/4 include a flexural strength of 720 MPa (to BS EN ISO178) and a tensile strength of 600 MPa (to BS 2782 Part 10:Method 1003). [Figure 6. Permaglass XGR2/4 typical mechanical properties table.]

Figure 2: Permali’s safety nets on the runway of HMS Queen Elizabeth, one of two British aircraft carriers

Steve Benn, Permali Technical Manager for composites commented: “The challenge was to achieve the fire performance required by this more demanding MoD FST standard without introducing the mechanical performance loss typically associated with the addition of fire retardant fillers. Working with our customers and the MoD regulatory team, we have managed to develop a technical solution which provides the right balance of properties needed for this next generation of naval stanchions. Permaglass XGR2/4 is now specified for manufacturing all four types of safety systems that Permali supplies for naval vessels”.

Proven naval deck safety systems

The Royal Navy (RN) and other navies around the world specify Permali’s lightweight, high performance GRP products to protect crew personnel and equipment on weather decks, flight decks, and walkways. All deck safety systems developed for Royal Naval vessels are MoD approved and rigorously tested to ensure that they meet specified DNV and Lloyds register regulatory standards.

Figure 3: Permali’s stanchions feature on HMS Arygll, a Type 23 frigate

Current naval vessels in service fitted with Permali supplied deck safety systems include: Visby class corvettes; RN Type 45 destroyers and Type 23 frigates; RFA Bay class support ships; the Queen Elizabeth-class aircraft carriers, famed for being the biggest, most advanced warships ever built for the Royal Navy. In addition to naval ships, the specialist polar exploration vessel the RRS Sir David Attenborough is also fitted with Permali deck safety systems to protect personnel while on the flight deck.

Figure 4: RRS Sir David Attenborough features Permali’s safety net system on it’s flight deck

GRP stanchion benefits

The use of a GRP composite material for stanchions, guardrails and net frames provide key in-service benefits over metallic alternatives, being lightweight, vibration free, corrosion resistant, low maintenance and non-conductive. For warships, a major operational benefit of using Permali’s composite stanchions for both deck safety nets frames and guardrail stanchions is that being non-metallic they produce a significantly reduced radar detection signature.

Figure 5: Permali’s safety net system features on HMS Daring, the first Type 45

Design flexibility

Permali offers a complete range of durable deck or hull mounted modular GRP composite stanchion designs to provide rigid guardrails, PARAFIL® synthetic rope guardrails and safety nets, or removable chains. Four standard stanchion styles are manufactured to accommodate the different types of vessels and deck area safety requirements:

- Type A stanchions (for fixed position guardrails)

- Type B stanchions (can fold fore and aft of the deck)

- Type D stanchions (fold onto the deck)

- Quick Release/Removable stanchions (for access areas)

Stanchion systems are supplied by Permali ‘ready to install’, complete with all the stainless steel deck base fixings, positive lock fittings and lug bolts specified for guardrail and net system designs. All fabricated composite stanchions, rigid guardrails, ‘quick release’ lift off gates and deck safety net frames are finish painted in-house with a two part paint system to the required vessel colours. Lift off gates are installed to provide easy access to specific deck areas for ‘over the side’ Replenishment at Sea (RAS) and to enable unobstructed helicopter maintenance.

Figure 6: Typical Properties Table – Extract from Permali Permaglass XGR2/4 technical data sheet

Bespoke designs and modifications are incorporated by Permali to suit the type of vessel and customised requirements such as: rail height and width, numbers of handrails, seated angle and type of hinge points; manual or automated operation. For aircraft carriers, approach lighting is included in flight deck net safety systems.

Permali designs, manufactures and supplies a vast range of bespoke FRP composite panels, components, and systems, based on a wide variety of resins, fibres, cores, and adhesives for a wide range of safety critical military and civil land, sea and air applications. The Permali product range also includes standard and bespoke Tuftane® aromatic thermoplastic polyurethane (TPU) elastic films.

To find out more head to our Naval Defence page

To get in touch email sales@permali.co.uk