Tuftane®

Permali manufactures a wide variety of Tuftane® branded thermoplastic polyurethane film products which are used in applications needing a tough, highly elastic flexible film as part of the product design.

We offer an extensive range of products and solutions to suit your needs. You can browse our catalogue, get a quote or make a list of what you need, and one of our specialists will be in touch.

Sectors

Permali specialises in composites, mouldings, sandwich panel systems, fibre reinforced plastic (FRP) composite laminates and Tuftane® TPU (thermoplastic polyurethane) films.

We work closely with customers across a diverse range of sectors:

Thermoplastic Polyurethane Films

Tuftane® films specified in many markets, applications and environments

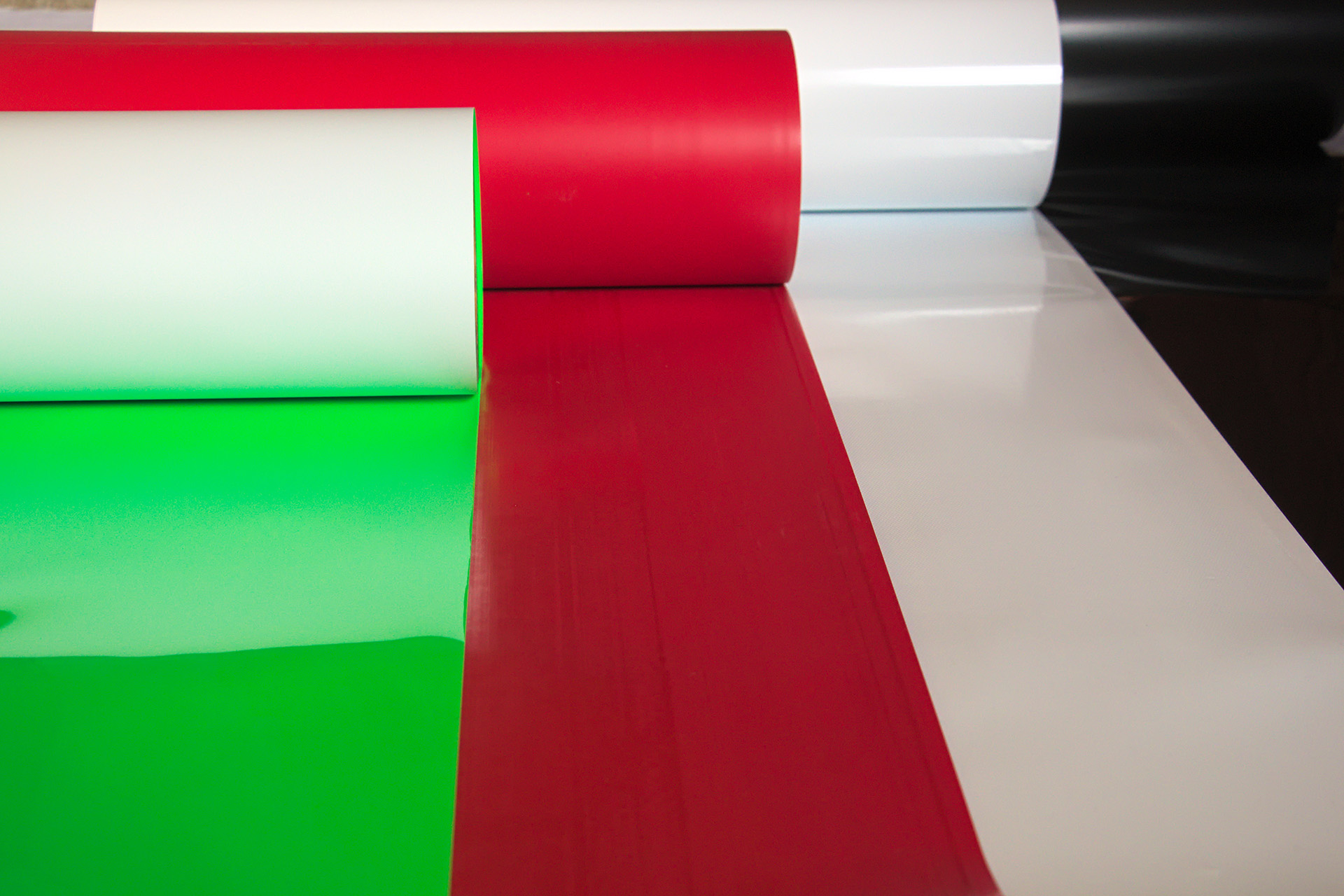

Tuftane® thermoplastic polyurethane films are specified in many markets, applications and environments: from artificial heart components, blood plasma bags and isolation tents in hospitals, to construction pipelining, aircraft furnishings, automotive parts and industrial valves. Tuftane® thermoplastic films come in a choice of over 30 grades, supplied in rolls up to 1.6 m wide, slit to width.

Tuftane® grades are blended using either polyester or polyether aromatic PU polymer technologies. Standard and bespoke grades with speciality additives options are available to order. The Permali technical team works closely with customers to ensure that cost effective thermoplastic material solutions are provided with the exact additives, technical specifications and properties needed to meet their processing, product performance and regulatory requirements. Our Tuftane® grades vary from very soft and flexible to hard and stiff and are blended to match end use applications.

All Tuftane® thermoplastic films are blown film extruded in-house, supplied to manufacturers on a roll, slit to width and rewound to order to optimise material utilisation and minimise scrap.

Tuftane® Thermoplastic Polyurethane films are easy for a manufacturer to work with using traditional techniques for combining, converting and finishing of plastic and rubber materials.

Processing & Finishing Options

Grade Selector

Standard Tuftane® Range – Grade Selector

Tuftane® film grades in polyester or polyether PU based formulations are available as standard, as listed in the downloadable grade selector table below:

Tuftane® polyester TPU grades – offer high mechanical properties, abrasion, heat ageing and chemical resistance.

Tuftane® polyether TPU grades – are ideal for applications where hydrolysis and microbial resistance along with high flexibility, even at very low temperatures, are critical performance attributes

Key features and benefits:

Variety of colours

Property additive options

Range of film hardness

Film thickness

Up to 650% elongation

Roll widths

Excellent resistance

Environmental resistance

Compliant

Soft to the touch

Easy to weld

Understanding Customer & Market Needs

Permali’s continued success with Tuftane® thermoplastic film solutions and thermoplastic composite materials in highly competitive global markets has been achieved by a combination of maintaining quality assurance, supply reliability and cost control, along with remaining technically innovative and responsive to changing market trends, regulatory standards and customer needs.