Medical Grade TPU Film

Medical Films

Polyurethane Film Solutions for Medical

Permali formulates and manufactures a wide variety of biocompatible Tuftane® thermoplastic polyurethane (TPU) films. Tuftane® Films are both flexible and elastomeric, with outstanding physical and mechanical properties. Permali’s Tuftane® TPU films are specified in bio-medical products, protective apparel and medical device applications for the professional and consumer healthcare markets.

Tuftane® products are used as laminating films, transparent membranes, fabric protective liners, barrier films, functional surface treatments, puncture–resistant transparent bags, inflatable bladders and many other applications.

As a leading PU film manufacturer, Permali produces a diverse range of Tuftane® films based on either polyester or polyether aromatic PU polymer technologies. These films combine flexibility with excellent abrasion wear, tear strength, and puncture resistance, even at low temperatures, and offer outstanding environmental resistance to gases, ozone, water, oil, and chemicals. This makes them excellent, tough, thin film material solutions for products that require flexibility and durability.

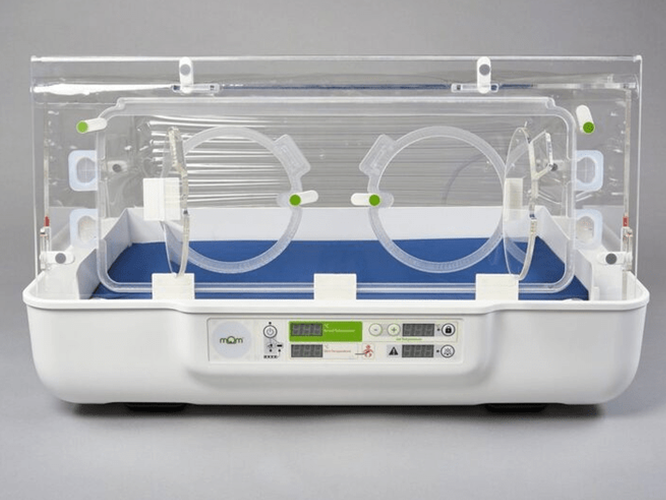

For manufacturers of medical equipment and healthcare products, specially formulated medical-grade Tuftane® have been developed to combine biocompatibility with excellent resistance to the growth of fungi and bacteria. Advanced additive technologies are used by Permali to produce Tuftane® films able to resist the growth of microbes, such as MRSA (S. Aureus) and E coli. All Tuftane® TPU films can be sterilised by either gamma irradiation or ethylene oxide.

Tuftane® medical grade TPU films are blended and blown film extruded in-house, slit to width and rewound to order in roll lengths to optimise productivity and minimise scrap.

Tuftane TPU Film Product Features & Benefits:

Film thickness

Roll widths

Roll hardness

Variety of colours

Environmentally resistant

Easy to convert

Specialty grades

Compliant

Soft and comfortable

Tear and puncture resistant

Sterile

Processing & Finishing Options for Polyurethane Films

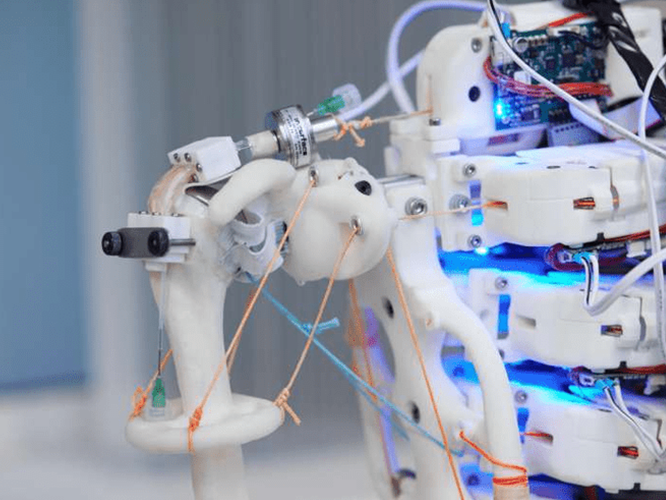

Tuftane® TPU films are easy for a manufacturer to work with using traditional techniques for combining, converting, and finishing of plastic and rubber materials. Commonly used film and sheet processing and finishing techniques include: vacuum thermoforming; heat sealing and laminating; adhesive and solvent bonding; cutting, punching and stamping; RF, HF and ultrasonic welding; embossing and printing.

Tuftane TPU films are specified by leading OEMs of pressure relief and redistribution mattresses used in hospital beds and across the healthcare sector. The specialist mattress design provides effective prevention and management of pressure ulcers.

Tuftane TPU films are ideal as the durable barrier layer in textile systems used for air, gel, and water-filled pressure relief mattress designs. The specified low hardness grade of Tuftane combines softness with high flexibility to ensure the required level of comfort. Additionally, Tuftane polyurethane film provides vital properties such as low permeability to air and water, excellent fatigue and puncture resistance, and resistance to hydrolysis and microbial growth.

Leading manufacturers of wipe-clean duvets, sheets, and pillows used in the healthcare sector take advantage of the processing and performance benefits of using medical Tuftane TPU films. Flexible speciality textiles are typically heat laminated or adhesive bonded to supporting foams and fabrics; both fabrication processes can be used with Tuftane clear TPU film.

For healthcare mattresses and bedding products, Permali offers manufacturers a choice of non-allergenic Tuftane polyurethane film grade options, formulated with functionality and performance properties as needed such as: flammability resistance, vapour permeability and contamination protection, including to MRSA resistance.

Tuftane TPU films are tough and impermeable, yet flexible and soft to the touch. This makes them an ideal film material for therapy gel pads and pressure relief pads on beds and wheelchairs. Comfort is combined with outstanding tear and puncture resistance, along with inherent liquid and gas barrier and anti-fungal properties.

Tuftane clear TPU film are also used for fabricating liquid or gas filled sealed bladders, which can be cost effectively manufactured using conventional HF and ultrasonic welding techniques.