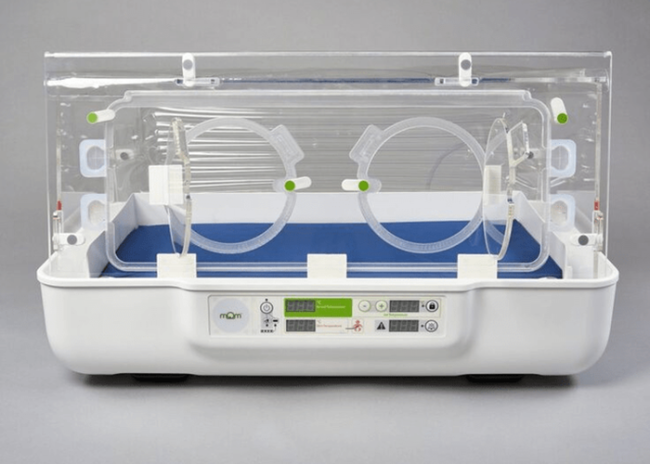

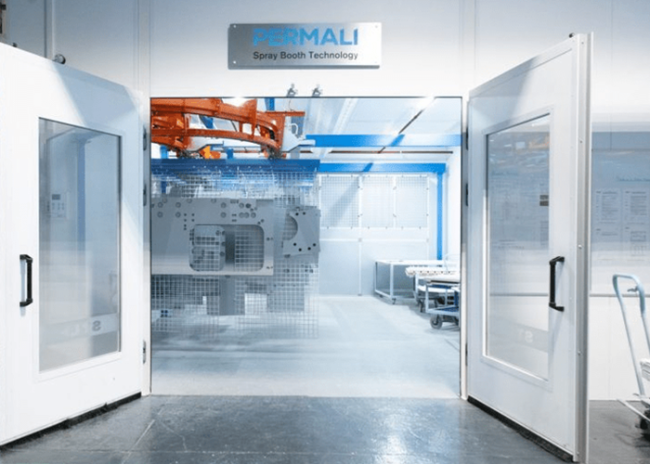

Permali are working with mOm Incubators to

provide Life-Saving Care for Babies

The mOm Incubator. Designed, developed, and manufactured in the UK, saving lives throughout the world. During his time at Loughborough University, while completing a bachelor’s degree in Product Design & Technology, James Roberts, now CEO and Founder of mOm Incubators, decided he wanted to help to reduce the number of premature baby deaths, on a…